ContiTech USA, Inc. - Our Story

How WCCO Belting started on a shoestring

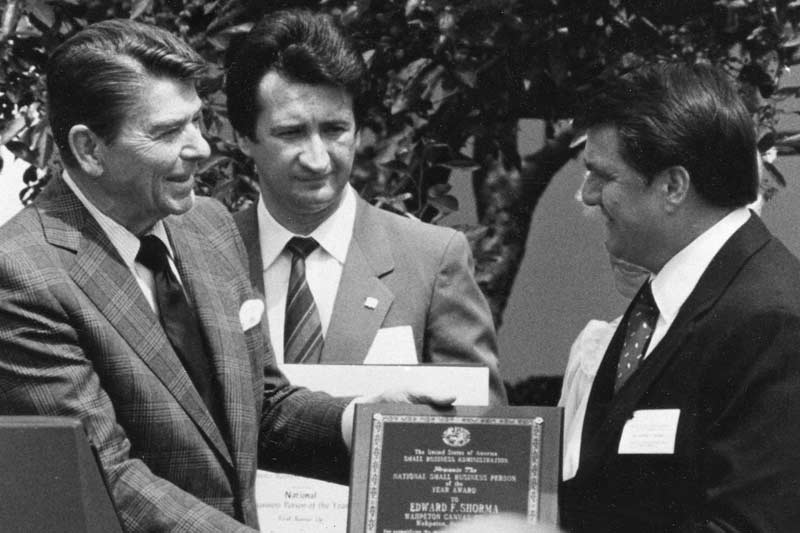

WCCO founder, Ed Shorma, was the son of immigrants and a farm boy who found himself on the world stage. He had a remarkable ability to establish a vision and work tirelessly to attain it. What was more impressive, however, was his way of inspiring other men and women with his drive and ambition so deeply that they, too, dedicated their lives in support of reaching the goals he set. This loyalty, combined with Ed’s dogged work ethic, helped him expand the family business into eight separate businesses and over one-thousand employees. This earned him the title of 1982 Small Business Person of the Year, a Small Business Administration award presented to him by President Ronald Reagan.

“Edward Shorma, a Korean War Veteran, mortgaged the family car and borrowed $1,500 in 1954 to buy a shoe repair shop in North Dakota. During his first year of operation, he grossed $5,400. Today, he has expanded it into a multi-million-dollar business providing jobs for hundreds of people.” President Ronald Reagan, 1982

So how did a shoe cobbler get into rubber belting? Ed had a knack for seeing a need and figuring out a way to fill it – typically using unconventional measures. (A characteristic that is still very prevalent in WCCO’s culture today.) Ed started using his sewing skills to repair farm truck seats and tarps. He’d go on to win contracts for creating canvas belting alongside burgeoning farm equipment manufacturers which set the path for Wahpeton Canvas Company (WCCO). After a cotton shortage in the 1980s, WCCO repurposed heat-sealing equipment from the kitchen cabinet industry (another of one of the eight Shorma family ventures) into a rubber vulcanization press. WCCO started to engineer rubber products for a growing list of domestic and international equipment manufacturers and distributors.

Today, WCCO Belting is a product brand under ContiTech USA, Inc., a Continental company. The Shorma family sold the business in 2022 to further launch its employees and products into the future.

WCCO Timeline

-

Edward F. Shorma, a Korean War veteran eager to conquer the American Dream, opened his first business as a shoe cobbler in Wahpeton, North Dakota

-

After using his sewing experience to repair swather canvas for local farmers, Shorma is inspired to manufacture his own and his first contract officially establishes Wahpeton Canvas Company (WCCO)

-

WCCO earns business from a renowned Canadian equipment manufacturer when Shorma invents a new technique to rivet slats to vinyl belting

-

As WCCO transitions from vinyl to rubber belting, its technology evolves using modified heat-sealing equipment from the kitchen cabinet industry to develop a proprietary vulcanization process

-

After successfully diversifying his business and producing assorted fabric, metal, wood, and rubber products, Ed Shorma is presented the National Small Business Person of the Year Award

-

WCCO founder Ed Shorma is inducted into the ND Entrepreneur Hall of Fame and is named the ND, SD, and MN Entrepreneur of the Year by Inc Magazine

-

WCCO continues to provide value through quality and customer satisfaction by becoming ISO 9001 certified

-

Tom Shorma, son of Ed Shorma, is named the CEO/President and he focuses the company on international expansion earning WCCO the 2003 ND Exporter of the Year Award

-

To create value through improved control over its operations, WCCO vertically integrates with its longtime calendering vendor

-

Because of its significant contribution to the growth of U.S. exports, WCCO Belting receives the Presidential “E” Award from the Department of Commerce

-

WCCO again demonstrates its innovation capabilities with a patented fabric technology that makes its new RAPTOR® Draper Belting the gold standard and highest performing draper in the world

-

WCCO accomplishes its third facility expansion in ten years and continues to deliver added value through lean processes and efficiencies

-

With a decade of international growth, WCCO is the first business in ND to receive the Presidential “E-Star” Award and the first in the state to become ISO 9001:2015 certified

-

WCCO is again recognized as one of the areas’ Top 50 Best Places to work by Prairie Business Magazine and moves forward on a project to add expand its maintenance area

-

The company unveils its new brand – TerraTech – representing a product line of rubber belting made using sustainable materials, its patented rubber compound made with soybean oil being the first in the industry worldwide

-

Its 65th anniversary is celebrated with a ribbon-cutting for its largest facility expansion to date, in addition to announcing two patent-pending designs at Agritechnica, the world’s largest agricultural fair

-

WCCO receives a Manufacturing Leadership Award from the National Association of Manufacturers, announces another patent-pending belt design at CONEXPO-CON/AGG, and is again named as one of the areas’ best places to work

-

In March, WCCO Belting announced its patent-pending Direct X belting design for crushing, grinding, sorting, screening, and piling operations for aggregate and recycling industries

-

WCCO’s patented Edge Defender™ cleat for combine harvest headers (draper platforms) becomes available to aftermarket distributors and to agricultural equipment manufacturers worldwide

-

WCCO receives the 50 Best Places to Work Award from Prairie Business Magazine for the seventh year. The company also earns the “Cooperate Leadership in Philanthropy Award” from The Association of Fundraising Professionals Northern Plains Chapter

-

WCCO Belting earns multiple awards including a place on Fast Company’s 100 Best Workplaces for Innovators list, two Manufacturing Leadership Awards, Exporter of the Year award from Export-Import Bank of the U.S., and four workplace safety awards from North Dakota Safety Council

-

Continental acquires WCCO Belting. With this acquisition, the technology company complements its conveyor belting customer portfolio and strengthens its Conveying Solutions business in the agricultural industry

-

The Wahpeton facility earns the 50 Best Places to Work Award from Prairie Business Magazine for the ninth time

-

The Wahpeton facility celebrates its first full year as part of Continental, continues to manufacture the global gold standard Raptor Draper Belting for OEMs worldwide, belts for other agriculture machinery, and for industries like playground equipment, roller coasters and mobile recycling

Latest News

Careers

Our dedicated team and friendly culture consistently rank WCCO as one of the best places to work in the area, and we are always looking for great people