Product Spotlight on Baler Belts, Blog Post

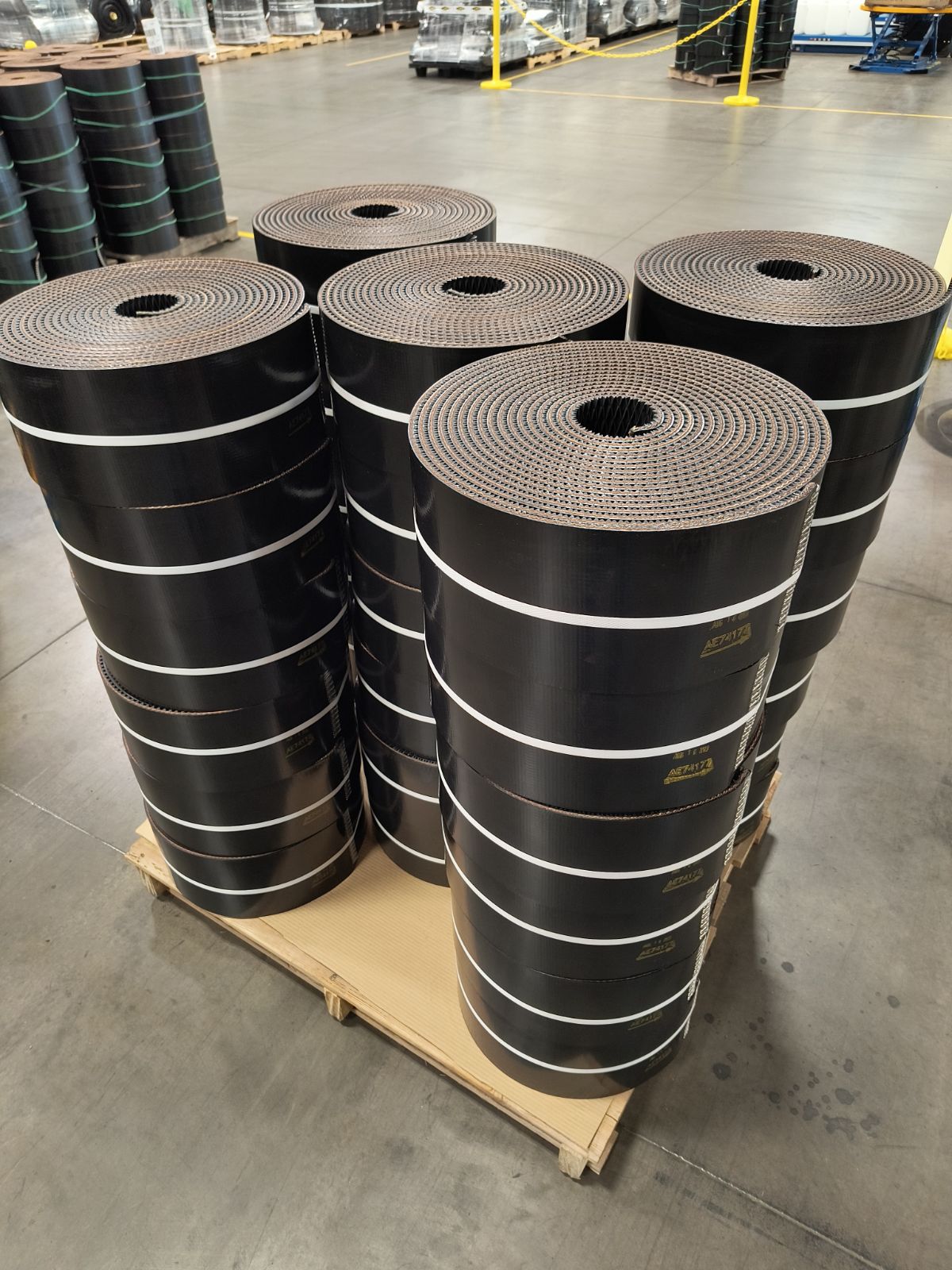

Balers are an essential component of a farm, increasing efficiency and output, but a baler is only as good as its belts. As a critical component, the equipment is heavily dependent on efficient and well-functioning belts for success. Continental’s WCCO Belting line of baler belts are manufactured with custom-engineered fabrics to increase belt strength and stiffness, which improves belt tracking and hook retention.

How do you know if its time replace your baler belts? Although the specific signs of deterioration vary, it’s still relatively easy to identify problems ahead of next season if you know where to look.

- Check the key indicators – belt texture, pattern and lacing. Baler belt length, width, texture or pattern (mini rough top, rough top, diamond top, etc.), overall gauge, lacing type, and other specifications are determined by the manufacturer according to the design and function of the baler. Pay close attention to the surface of your baler belt. If the texture or pattern is wearing down, it could indicate that your belt isn’t working at its full capacity because it will pick up the crop and bale differently. Fraying of fabric plies or missing rubber on the cover are also indications that it’s time to consider a new belt.

- Replace a full set for the most optimal for performance. Baler equipment functions the most optimally if the whole set of baler belts is replaced at the same time. Among other tangible benefits, this helps to ensure even tensioning. To determine if you have consistent tension across the set of baler belts, run the equipment dry to see if one of the belts is moving or flopping around more. If it is, consider replacing the set to ensure effective baling next season.

- Replace a partial set or repair the splice/belt to save downtime. It is possible to replace only one or two belts in a set. In this case, it’s critical to measure the length of the belts and order to that new length. Baler belts are made of rubber and fabric that can stretch and flex over time. You need the measurement of the belts being replaced rather than the length when installed. If the new belts are shorter than the others on the machine, it can affect output and lead to premature belt failure and equipment malfunction.

Preventative Maintenance

Sourcing quality replacement parts and components, and following the care instructions for each, will reduce the total cost of ownership of a machine.

For example, the WCCO Belting line of products is manufactured with a rubber compound designed with UV protection to withstand damage from sunlight. Over time and through exposure to sun and other elements, the white residue you may see on a belt is its natural protectant. As the waxes in the rubber start to bloom and lose moisture, the cover will start to crack. Storing machinery with belting indoors is a good way to prevent these issues. If there isn’t a place to store equipment inside, achieving coverage with a tarp is a relatively easy way to extend the life of the belt. Another key preventative maintenance idea is to lower/remove the belt tension when the baler isn’t in use, especially if the baler is stored in a climate that is cold in the winter. This will prevent the inevitable cold belt shrinkage that will over-tension the belt and create undue stress on the splice joints. One other key maintenance item is replacing the lacing pin/cable annually to maximize your belt splice life.

While the thought of finishing a harvest season and saying goodbye to the equipment until the next season may be appealing, spending a little more time with your equipment post-harvest will save time and money in the future. Specific benefits include:

- Taking care of your belts in the off-season will prevent in-season downtime.

- There is a cost-benefit to assessing your machinery in the off-season and making replacement purchases at that time, when you’re likely to get a lower price than in the height of the season.

- Checking your equipment can offer peace of mind knowing your machine will run smoothly during harvest and better protect your bottom-line.

While there may not be a tried and true “test” that you can use to see if your machinery or belt is still operating at 100% capacity, using these tips and tricks before or after every harvest season could increase the longevity of your belt, improve the operating efficiency of your equipment, and help ensure there won’t be any surprises heading into next season. For more information, contact your dealer or our team at sales@wccobelt.com.